宣纸制作工艺揭秘:感受中国传统造纸术的精湛

势大力沉

2024-11-17 15:01:09

0次

宣纸制作工艺揭秘:感受中国传统造纸术的精湛

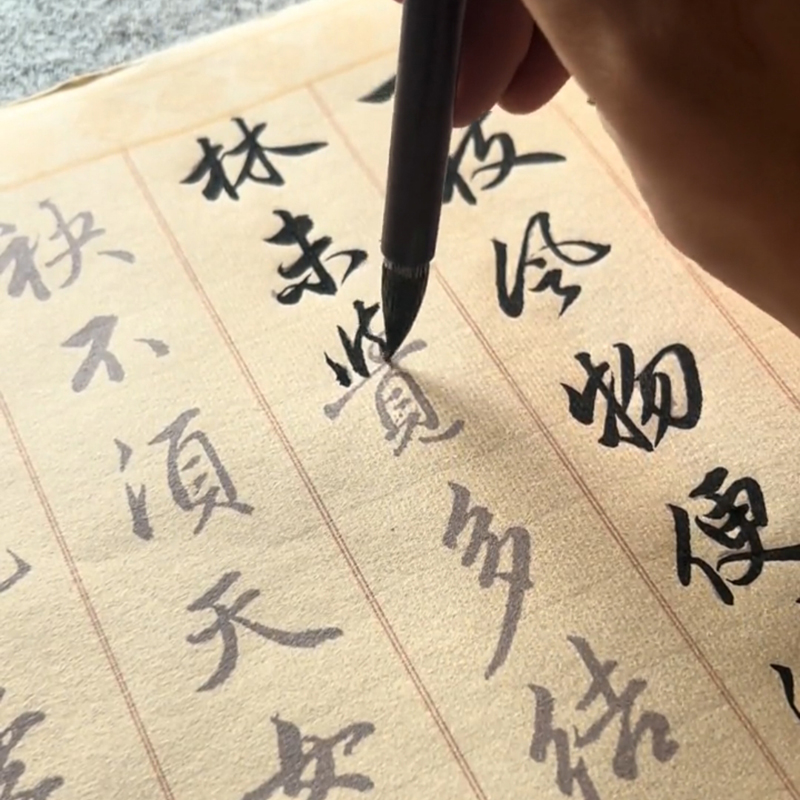

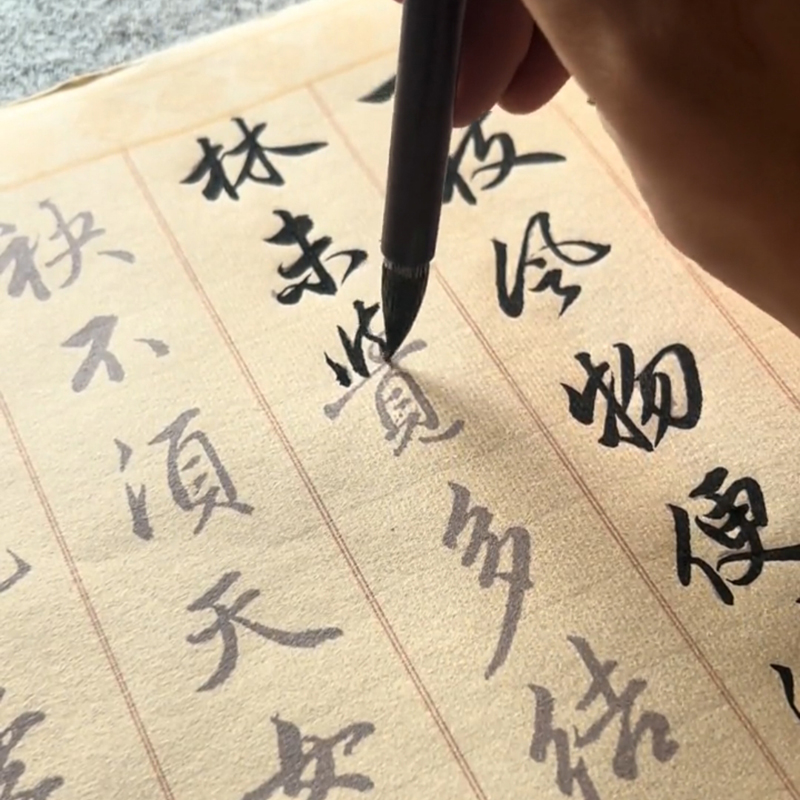

在中国传统的手工艺中,宣纸制作工艺无疑是一颗璀璨的明珠。它不仅是中国书画艺术的重要载体,更是中国传统文化的象征之一。它的独特制作工艺与高超的艺术效果吸引了无数人的关注,也见证了中国古代人民的智慧和才华。今天,我们将带您深入探索宣纸的制作工艺,感受中国传统造纸术的精湛。

一、宣纸制作工艺简介

宣纸的制作过程相当复杂,主要分为选材、浸泡、打浆、晒网、晒纸等步骤。其中,选材是宣纸制作的第一步,选用的是青檀树皮和沙田稻草等天然植物纤维作为原料。这些原料经过浸泡、蒸煮、漂洗等工序后,再经过打浆、晒网等环节,最终形成一张张洁白细腻、质地坚韧的宣纸。

二、选材与浸泡

选材是宣纸制作的关键步骤之一。选用青檀树皮和沙田稻草等天然植物纤维作为原料,这些原料需要经过严格的筛选和挑选。然后,将选好的原料进行浸泡,使其软化并去除杂质。这一步需要耗费大量的时间和人力,但却是制作高质量宣纸的基础。

三、打浆与晒网

打浆是宣纸制作的重要环节之一。将浸泡好的原料进行破碎、研磨,使其成为纸浆。接着,通过晒网将纸浆均匀地分布在网面上,形成纸张的基本形状。这一步需要精湛的技艺和丰富的经验,因为纸张的质量和均匀度直接影响到最终的产品质量。

四、晒纸与整理

晒纸是将已经形成的纸张晾晒在阳光下,使其干燥。这一步需要选择适宜的天气和地点,以保证纸张能够充分晒干。最后,对晒干的纸张进行整理和修剪,使其达到规定的尺寸和形状。

五、中国传统造纸术的精湛之处

宣纸制作工艺的精湛之处在于其独特的技术和严格的制作流程。从选材到成纸,每一个环节都需要精湛的技艺和丰富的经验。同时,宣纸的制作过程中还融入了古代人民的智慧和创意,使其具有独特的艺术效果和文化内涵。此外,宣纸的制作还需要高度的环保意识,选用天然植物纤维作为原料,不添加任何化学物质,保证了产品的环保性和健康性。

六、总结

宣纸制作工艺是中国传统文化的重要组成部分,它不仅展示了中国古代人民的智慧和才华,还传承了中华民族的优秀文化传统。通过了解宣纸的制作工艺,我们可以感受到中国传统造纸术的精湛之处。在今天这个数字化时代,我们更应该珍惜和传承这些传统手工艺,让它们继续发扬光大。

晒纸是将已经形成的纸张晾晒在阳光下,使其干燥。这一步需要选择适宜的天气和地点,以保证纸张能够充分晒干。最后,对晒干的纸张进行整理和修剪,使其达到规定的尺寸和形状。

五、中国传统造纸术的精湛之处

宣纸制作工艺的精湛之处在于其独特的技术和严格的制作流程。从选材到成纸,每一个环节都需要精湛的技艺和丰富的经验。同时,宣纸的制作过程中还融入了古代人民的智慧和创意,使其具有独特的艺术效果和文化内涵。此外,宣纸的制作还需要高度的环保意识,选用天然植物纤维作为原料,不添加任何化学物质,保证了产品的环保性和健康性。

六、总结

宣纸制作工艺是中国传统文化的重要组成部分,它不仅展示了中国古代人民的智慧和才华,还传承了中华民族的优秀文化传统。通过了解宣纸的制作工艺,我们可以感受到中国传统造纸术的精湛之处。在今天这个数字化时代,我们更应该珍惜和传承这些传统手工艺,让它们继续发扬光大。

Revealing the Secrets of Xuan Paper Manufacturing Process: Feeling the Exquisite Skills of Chinese Traditional Paper-making Art

In the realm of traditional Chinese craftsmanship, the production of Xuan paper is undoubtedly a brilliant jewel. It is not only an important carrier of Chinese painting and calligraphy art, but also one of the symbols of traditional Chinese culture. Its unique manufacturing process and exquisite artistic effects have attracted the attention of countless people, attesting to the wisdom and talent of ancient Chinese people. Today, we will take you to explore the production process of Xuan paper and experience the exquisite skills of Chinese traditional paper-making.

Revealing the Secrets of Xuan Paper Manufacturing Process: Feeling the Exquisite Skills of Chinese Traditional Paper-making Art

In the realm of traditional Chinese craftsmanship, the production of Xuan paper is undoubtedly a brilliant jewel. It is not only an important carrier of Chinese painting and calligraphy art, but also one of the symbols of traditional Chinese culture. Its unique manufacturing process and exquisite artistic effects have attracted the attention of countless people, attesting to the wisdom and talent of ancient Chinese people. Today, we will take you to explore the production process of Xuan paper and experience the exquisite skills of Chinese traditional paper-making.

The production process of Xuan paper is quite complex, mainly divided into steps such as material selection, soaking, pulping, sieving, and drying. The raw materials, such as bark from the Qingtan tree and straw from Shatian rice fields, are selected and soaked in water after being processed through steps such as steaming, boiling, and washing. Then, through pulping and sieving processes, a clean, fine, and tough piece of Xuan paper is finally formed.

2. Material Selection and Soaking

Material selection is one of the key steps in the production of Xuan paper. Natural plant fibers such as bark from the Qingtan tree and straw from Shatian rice fields are selected as raw materials, which require rigorous screening and selection. Then, the selected raw materials are soaked in water to soften them and remove impurities. This step takes a lot of time and manpower, but it is the foundation for producing high-quality Xuan paper.

3. Pulping and Sieving

Pulping is one of the important steps in the production of Xuan paper. The soaked raw materials are crushed and ground to become pulp. Then, through sieving, the pulp is evenly distributed on the screen to form the basic shape of the paper. This step requires exquisite skills and rich experience because the quality and uniformity of the paper directly affect the final product quality.

4.

The production process of Xuan paper is quite complex, mainly divided into steps such as material selection, soaking, pulping, sieving, and drying. The raw materials, such as bark from the Qingtan tree and straw from Shatian rice fields, are selected and soaked in water after being processed through steps such as steaming, boiling, and washing. Then, through pulping and sieving processes, a clean, fine, and tough piece of Xuan paper is finally formed.

2. Material Selection and Soaking

Material selection is one of the key steps in the production of Xuan paper. Natural plant fibers such as bark from the Qingtan tree and straw from Shatian rice fields are selected as raw materials, which require rigorous screening and selection. Then, the selected raw materials are soaked in water to soften them and remove impurities. This step takes a lot of time and manpower, but it is the foundation for producing high-quality Xuan paper.

3. Pulping and Sieving

Pulping is one of the important steps in the production of Xuan paper. The soaked raw materials are crushed and ground to become pulp. Then, through sieving, the pulp is evenly distributed on the screen to form the basic shape of the paper. This step requires exquisite skills and rich experience because the quality and uniformity of the paper directly affect the final product quality.

4.

【宣纸】超多笔画6千划练习楷书描红毛笔软笔字帖宣纸初学入门培训班送视售价:13.80元 领券价:11元 邮费:0.00

商家:致远斋文房 年销量:6000+

【宣纸】四尺六尺八尺微喷国展书法作品纸仿古宣纸行书对开半生熟信笺蜡染售价:29.90元 领券价:31.9元 邮费:3.00

商家:粲然文房书画 年销量:5000+

1. Introduction to the Production Process of Xuan Paper

【宣纸】赵孟俯行书典范作品梅花诗描红长卷临摹毛笔字帖宣纸3遍装6米长卷售价:24.00元 领券价:24元 邮费:0.00

商家:致远斋文房 年销量:5000+

相关内容

热门资讯

传统与现代:解读宣纸的独特魅力

摘要:

宣纸凭借其独特工艺和魅力,融合传统与现代,展现中华文化深厚底蕴。其细腻质地、吸墨润墨及耐久...

宣纸——传统工艺与现代审美的完...

宣纸是传统工艺与现代审美的完美结合,以青檀树皮为原料,经复杂工艺制成,具有深厚文化底蕴和艺术价值。它...

宣纸在当代艺术创作中的应用

摘要:

宣纸在当代艺术中广泛应用,对传统文化有传承作用,促进艺术创新,并提升作品观赏性和收藏价值。...

宣纸的多样性:从古至今的艺术创...

本文探讨了宣纸的多样性和从古至今的艺术创新。宣纸种类繁多,具有独特性能,被用于各种艺术创作。从古代的...

书法与绘画的绝配——宣纸的独特...

摘要:

宣纸作为中国传统文化艺术材料,以其独特制造工艺和优良物理特性,成为书法与绘画的绝配。其原材...

宣纸的艺术世界:中国千年工艺的...

宣纸作为中国千年工艺的瑰宝,以其独特材质和细腻纹理成为艺术创作的重要载体和文化象征。其千年传承的工艺...

宣纸的独特之处:为何它是艺术家...

摘要:

宣纸因独特原材料和精湛制作工艺,具有吸墨润墨性,是艺术创作的首选。其文化价值传承,使宣纸成...

宣纸技艺传承与发展:探索现代艺...

本文探讨宣纸技艺的传承与发展,指出其作为中国传统文化重要载体的独特性,并分析现代艺术如何借助宣纸技艺...

宣纸与书法艺术:千年传承的完美...

摘要:宣纸与书法艺术相得益彰,共同传承中华文化精髓。宣纸独特质地为书法提供创作基础,书法深邃内涵赋予...

宣纸的独特之处:为何成为艺术家...

宣纸因独特制作工艺、卓越物理特性、丰富文化内涵,成为艺术家首选。其吸墨、润墨性强,可展现丰富层次和立...