宣纸制作工艺揭秘:从原材料到成品的匠心之作

势大力沉

2024-12-08 07:27:41

0次

宣纸制作工艺揭秘:从原材料到成品的匠心之作

一、引言

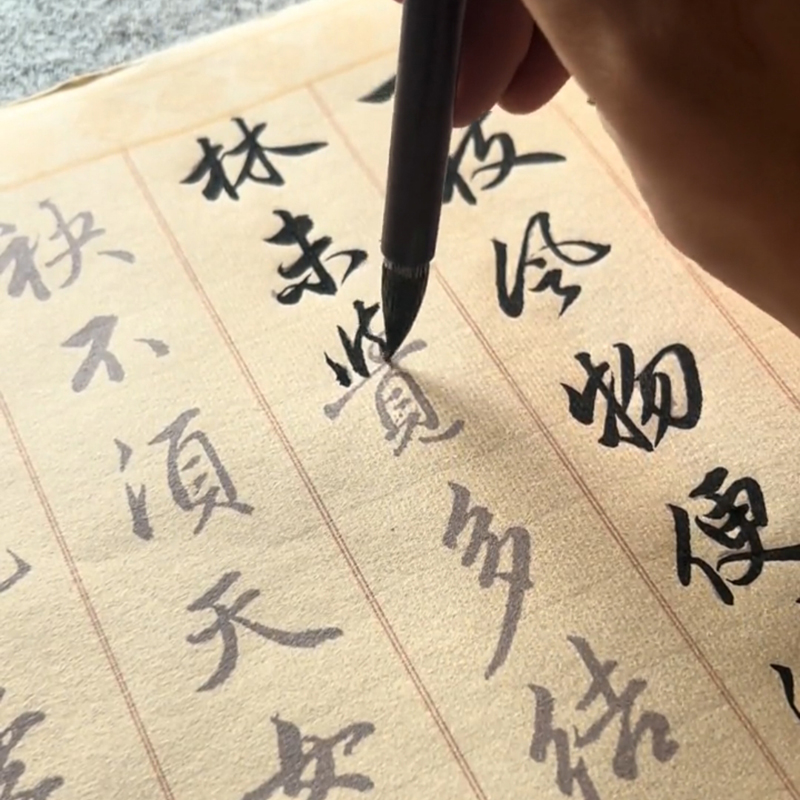

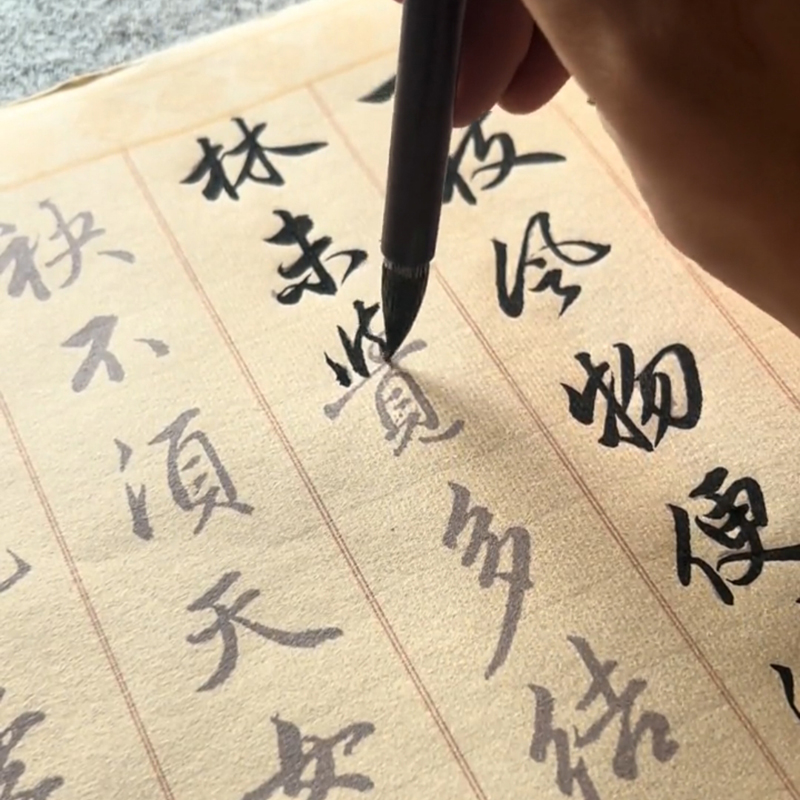

宣纸,作为中国传统的四大名纸之一,以其独特的制作工艺和优良的书画性能,享誉全球。它承载了千年文化传承的底蕴,成为了一种代表东方匠心之作的特殊工艺品。今天,我们将揭秘宣纸制作工艺的全程,从原材料的选择到成品的完成,深入解析其中的每一道工序和独特之处。

二、原材料的选择

宣纸的原材料主要选用青檀、构树等皮料,经过漂洗、切割、煮炼等工序,成为纤维均匀、无杂质的原材料。在这一阶段,选材至关重要,只有选用质地优良的原材料,才能保证后续的工序顺利进行。

三、浆料制作

四、网面捞纸

完成浆料制作后,下一步是网面捞纸。这个步骤需要将浆料倒在特制的竹帘上,用竹帘捞起纸张,使其形成一定的厚度和质地。这个过程中需要掌握好捞纸的力度和速度,以及竹帘的质地和网孔大小等因素,这些都会直接影响到宣纸的成品效果。

五、晾晒与加工

捞好的纸张需要晾晒和加工。在晾晒过程中,需要选择合适的环境和气候条件,以保证纸张能够自然晾干。而在加工过程中,还需要对纸张进行修剪、打磨、磨光等工序,使其达到所需的尺寸和光滑度。这些工序都需要匠心独运的技艺和经验。

六、成品检验与包装

最后一步是成品检验与包装。在成品检验阶段,需要对每一批次的宣纸进行质量检测和评估,确保其符合规定的标准和要求。而包装阶段则需要将合格的宣纸进行包装和标识,以便于销售和运输。

七、英文翻译

Revealing the Secrets of Xuan Paper Production: A Work of Art from Raw Materials to Finished Product

Xuan paper, as one of the four famous Chinese papers, is renowned worldwide for its unique production process and excellent performance in painting and calligraphy. It carries the heritage of thousands of years of cultural transmission and has become a special craftwork representing the ingenuity of the East. Today, we will reveal the entire process of Xuan paper production, from the selection of raw materials to the completion of the finished product, delving into each step and its uniqueness.

1. Selection of Raw Materials: Xuan paper mainly uses raw materials such as Qingtao and Kougu tree bark, which are processed through washing, cutting, boiling, and other steps to become uniformly fibrous and impurity-free materials. In this stage, material selection is crucial as only high-quality raw materials can ensure smooth progress in subsequent steps.

2. Pulp Production: The next step is to produce the pulp. This involves beating the selected raw materials to form a viscous and plastic pulp. This process requires mastery of time and temperature to achieve the best beating effect. Additionally, natural plant or mineral pigments are added to the pulp to give the resulting Xuan paper a certain color and texture.

3. Screening and Paper Making: After completing the pulp production, the next step is screening and paper making. This involves pouring the pulp onto a specially made bamboo screen and using the bamboo screen to lift and form the paper to a certain thickness and texture. This process requires mastery of the strength and speed of paper making, as well as the texture and mesh size of the bamboo screen, which directly affects the final product's quality.

4. Drying and Processing: The paper that has been lifted needs to be dried and processed. During the drying process, suitable environmental and climate conditions need to be selected to ensure that the paper can dry naturally. In the processing stage, further steps such as trimming, grinding, and polishing are required to achieve the desired size and smoothness. These steps all require unique skills and experience.

5. Quality Inspection and Packaging: The final step is quality inspection and packaging. In the quality inspection stage, every batch of Xuan paper is inspected for quality and assessed to ensure it meets specified standards and requirements. The packaging stage involves packaging and labeling qualified Xuan paper for sale and transportation.

四、网面捞纸

完成浆料制作后,下一步是网面捞纸。这个步骤需要将浆料倒在特制的竹帘上,用竹帘捞起纸张,使其形成一定的厚度和质地。这个过程中需要掌握好捞纸的力度和速度,以及竹帘的质地和网孔大小等因素,这些都会直接影响到宣纸的成品效果。

五、晾晒与加工

捞好的纸张需要晾晒和加工。在晾晒过程中,需要选择合适的环境和气候条件,以保证纸张能够自然晾干。而在加工过程中,还需要对纸张进行修剪、打磨、磨光等工序,使其达到所需的尺寸和光滑度。这些工序都需要匠心独运的技艺和经验。

六、成品检验与包装

最后一步是成品检验与包装。在成品检验阶段,需要对每一批次的宣纸进行质量检测和评估,确保其符合规定的标准和要求。而包装阶段则需要将合格的宣纸进行包装和标识,以便于销售和运输。

七、英文翻译

Revealing the Secrets of Xuan Paper Production: A Work of Art from Raw Materials to Finished Product

Xuan paper, as one of the four famous Chinese papers, is renowned worldwide for its unique production process and excellent performance in painting and calligraphy. It carries the heritage of thousands of years of cultural transmission and has become a special craftwork representing the ingenuity of the East. Today, we will reveal the entire process of Xuan paper production, from the selection of raw materials to the completion of the finished product, delving into each step and its uniqueness.

1. Selection of Raw Materials: Xuan paper mainly uses raw materials such as Qingtao and Kougu tree bark, which are processed through washing, cutting, boiling, and other steps to become uniformly fibrous and impurity-free materials. In this stage, material selection is crucial as only high-quality raw materials can ensure smooth progress in subsequent steps.

2. Pulp Production: The next step is to produce the pulp. This involves beating the selected raw materials to form a viscous and plastic pulp. This process requires mastery of time and temperature to achieve the best beating effect. Additionally, natural plant or mineral pigments are added to the pulp to give the resulting Xuan paper a certain color and texture.

3. Screening and Paper Making: After completing the pulp production, the next step is screening and paper making. This involves pouring the pulp onto a specially made bamboo screen and using the bamboo screen to lift and form the paper to a certain thickness and texture. This process requires mastery of the strength and speed of paper making, as well as the texture and mesh size of the bamboo screen, which directly affects the final product's quality.

4. Drying and Processing: The paper that has been lifted needs to be dried and processed. During the drying process, suitable environmental and climate conditions need to be selected to ensure that the paper can dry naturally. In the processing stage, further steps such as trimming, grinding, and polishing are required to achieve the desired size and smoothness. These steps all require unique skills and experience.

5. Quality Inspection and Packaging: The final step is quality inspection and packaging. In the quality inspection stage, every batch of Xuan paper is inspected for quality and assessed to ensure it meets specified standards and requirements. The packaging stage involves packaging and labeling qualified Xuan paper for sale and transportation.

接下来是浆料制作的过程。这一步需要将选好的原材料进行打浆,使其形成一种具有粘性和可塑性的浆料。这个过程中需要掌握好时间和火候,使得打浆效果达到最佳状态。同时,还需在浆料中加入一些天然植物颜料或矿物颜料,使制成的宣纸具有一定的色彩和质地。

【宣纸】超多笔画6千划练习楷书描红毛笔软笔字帖宣纸初学入门培训班送视售价:13.80元 领券价:11元 邮费:0.00

总结:宣纸的制作过程是一个充满匠心和技艺的过程,从原材料的选择到成品的完成,每一步都需要精湛的技艺和经验。这种独特的工艺品不仅承载了

【宣纸】赵孟俯行书典范作品梅花诗描红长卷临摹毛笔字帖宣纸3遍装6米长卷售价:19.80元 领券价:19.8元 邮费:0.00

相关内容

热门资讯

传统与现代:解读宣纸的独特魅力

摘要:

宣纸凭借其独特工艺和魅力,融合传统与现代,展现中华文化深厚底蕴。其细腻质地、吸墨润墨及耐久...

宣纸——传统工艺与现代审美的完...

宣纸是传统工艺与现代审美的完美结合,以青檀树皮为原料,经复杂工艺制成,具有深厚文化底蕴和艺术价值。它...

宣纸在当代艺术创作中的应用

摘要:

宣纸在当代艺术中广泛应用,对传统文化有传承作用,促进艺术创新,并提升作品观赏性和收藏价值。...

宣纸的多样性:从古至今的艺术创...

本文探讨了宣纸的多样性和从古至今的艺术创新。宣纸种类繁多,具有独特性能,被用于各种艺术创作。从古代的...

书法与绘画的绝配——宣纸的独特...

摘要:

宣纸作为中国传统文化艺术材料,以其独特制造工艺和优良物理特性,成为书法与绘画的绝配。其原材...

宣纸的艺术世界:中国千年工艺的...

宣纸作为中国千年工艺的瑰宝,以其独特材质和细腻纹理成为艺术创作的重要载体和文化象征。其千年传承的工艺...

宣纸的独特之处:为何它是艺术家...

摘要:

宣纸因独特原材料和精湛制作工艺,具有吸墨润墨性,是艺术创作的首选。其文化价值传承,使宣纸成...

宣纸技艺传承与发展:探索现代艺...

本文探讨宣纸技艺的传承与发展,指出其作为中国传统文化重要载体的独特性,并分析现代艺术如何借助宣纸技艺...

宣纸与书法艺术:千年传承的完美...

摘要:宣纸与书法艺术相得益彰,共同传承中华文化精髓。宣纸独特质地为书法提供创作基础,书法深邃内涵赋予...

宣纸的独特之处:为何成为艺术家...

宣纸因独特制作工艺、卓越物理特性、丰富文化内涵,成为艺术家首选。其吸墨、润墨性强,可展现丰富层次和立...