宣纸制作工艺:从原材料到成品的神奇之旅

势大力沉

2024-12-16 03:54:49

0次

宣纸制作工艺:从原材料到成品的神奇之旅

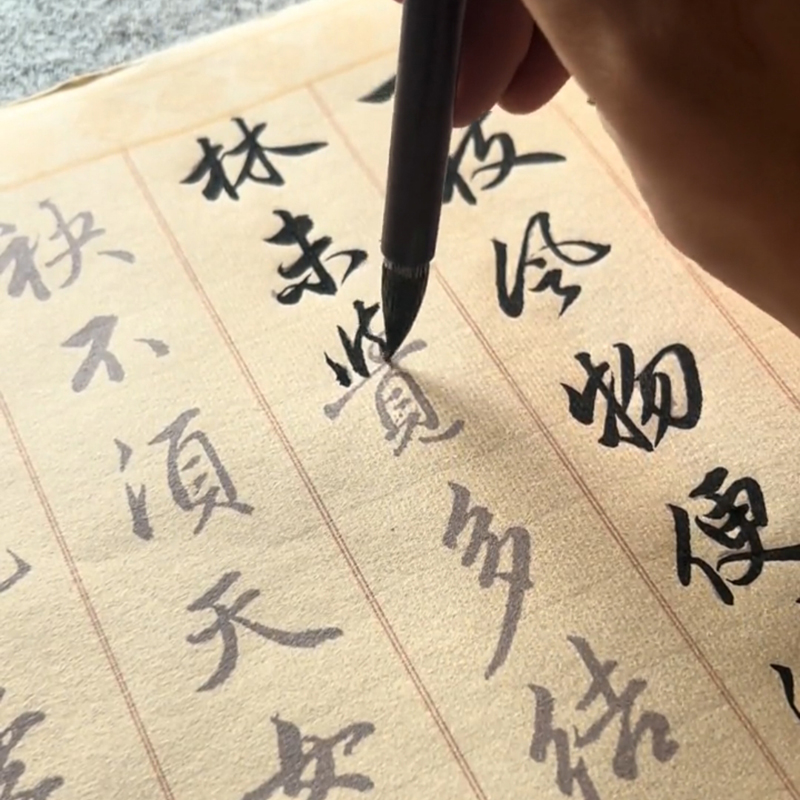

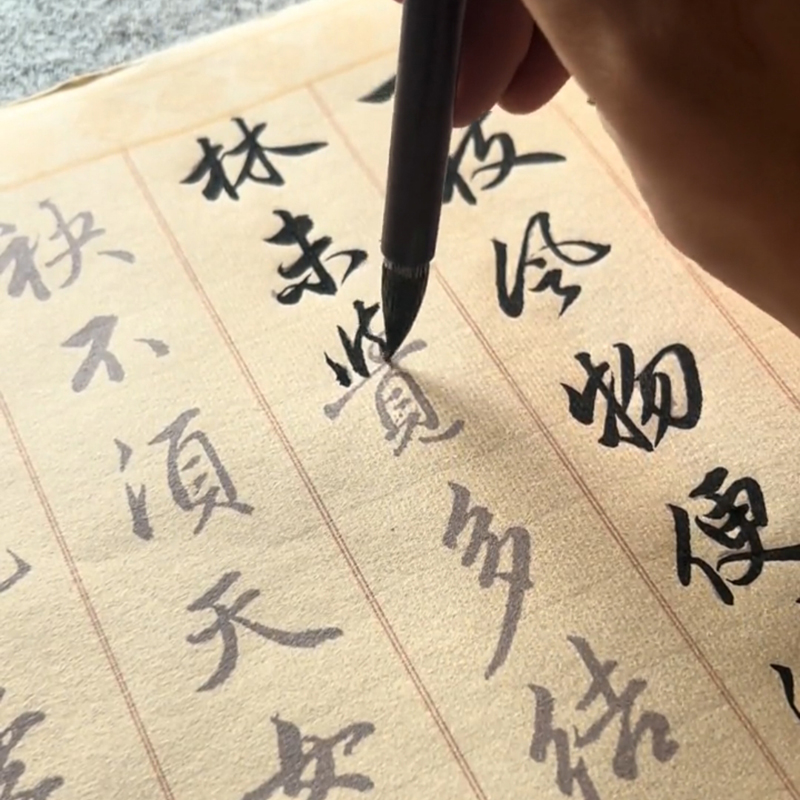

在中国传统艺术中,宣纸扮演着举足轻重的角色。它以其独特的质地、细腻的触感和持久的保存性,成为了书画家们的首选。那么,让我们开始这场从原材料到成品的神奇之旅,探索宣纸的制作工艺。

一、原材料的采集与处理

宣纸的主要原材料是青檀树皮和沙田稻草。首先,从青檀树上剥下的树皮经过清洗、晒干、研磨等步骤,使其成为一种优质的纤维原料。同时,沙田稻草也是宣纸制作的重要原料,其纤维长、强度高,为宣纸提供了良好的物理性能。

二、混合与搅拌

三、抄纸与晾干

接下来是抄纸的步骤。抄纸师将混合好的纸浆放在框架上,用特殊的工具将纸浆均匀地铺开,形成纸张的初步形态。这个过程需要高超的技巧和丰富的经验,以保证纸张的厚薄均匀、无杂质。随后,将抄好的纸张晾干,这个过程需要一定的时间,以确保纸张的干燥程度适中。

四、剪裁与整理

当纸张干燥后,进入剪裁环节。根据不同的需求,将纸张剪裁成合适的大小和形状。然后进行整理,去除纸中的杂质和不良部分,使每一张纸都达到一定的质量标准。

五、成品检验与包装

最后是成品检验与包装环节。对每一批次的宣纸进行质量检查,确保其符合规定的标准。然后进行包装,包装材料通常为纸质或布质包装袋,以保护宣纸不受外界环境的损害。

至此,一场从原材料到成品的神奇之旅就结束了。宣纸的制作工艺虽然复杂,但每一步都充满了匠人的心血和智慧。正是这些精心制作的宣纸,为中国的书画艺术提供了无尽的创作可能。

The Magic Journey of Xuan Paper Production Process: From Raw Materials to Finished Products

In Chinese traditional art, Xuan paper plays a pivotal role. With its unique texture, delicate touch, and long-lasting preservation, it has become the first choice for calligraphers and painters. Let's embark on a magical journey from raw materials to finished products and explore the production process of Xuan paper.

Firstly, the collection and processing of raw materials. The main raw materials for Xuan paper are the bark of the Qingtan tree and sandy rice straw. The bark is cleaned, dried, and ground after being stripped from the tree, becoming a high-quality fiber raw material. At the same time, sandy rice straw is also an important raw material for Xuan paper production, with its long fibers and high strength providing good physical properties for Xuan paper.

Secondly, mixing and stirring. The fibers of bark and rice straw are mixed and then mixed with water. This step is to achieve a uniform state of fully mixed fibers. During the mixing process, some chemicals such as alkaline substances and bleaching agents are added to adjust the properties and color of the fibers.

Thirdly, paper-making and drying. The next step is paper-making. The paper-making master puts the mixed pulp on a frame and uses special tools to evenly spread the pulp to form the initial shape of the paper. This process requires high-level skills and rich experience to ensure that the paper is evenly thick without impurities. Then, the copied paper is dried, which takes a certain amount of time to ensure that the paper is moderately dry.

Fourthly, cutting and sorting. After the paper is dry, it enters the cutting process. According to different needs, the paper is cut into appropriate sizes and shapes. Then it is sorted to remove impurities and poor parts in the paper to achieve a certain quality standard for each sheet of paper.

三、抄纸与晾干

接下来是抄纸的步骤。抄纸师将混合好的纸浆放在框架上,用特殊的工具将纸浆均匀地铺开,形成纸张的初步形态。这个过程需要高超的技巧和丰富的经验,以保证纸张的厚薄均匀、无杂质。随后,将抄好的纸张晾干,这个过程需要一定的时间,以确保纸张的干燥程度适中。

四、剪裁与整理

当纸张干燥后,进入剪裁环节。根据不同的需求,将纸张剪裁成合适的大小和形状。然后进行整理,去除纸中的杂质和不良部分,使每一张纸都达到一定的质量标准。

五、成品检验与包装

最后是成品检验与包装环节。对每一批次的宣纸进行质量检查,确保其符合规定的标准。然后进行包装,包装材料通常为纸质或布质包装袋,以保护宣纸不受外界环境的损害。

至此,一场从原材料到成品的神奇之旅就结束了。宣纸的制作工艺虽然复杂,但每一步都充满了匠人的心血和智慧。正是这些精心制作的宣纸,为中国的书画艺术提供了无尽的创作可能。

The Magic Journey of Xuan Paper Production Process: From Raw Materials to Finished Products

In Chinese traditional art, Xuan paper plays a pivotal role. With its unique texture, delicate touch, and long-lasting preservation, it has become the first choice for calligraphers and painters. Let's embark on a magical journey from raw materials to finished products and explore the production process of Xuan paper.

Firstly, the collection and processing of raw materials. The main raw materials for Xuan paper are the bark of the Qingtan tree and sandy rice straw. The bark is cleaned, dried, and ground after being stripped from the tree, becoming a high-quality fiber raw material. At the same time, sandy rice straw is also an important raw material for Xuan paper production, with its long fibers and high strength providing good physical properties for Xuan paper.

Secondly, mixing and stirring. The fibers of bark and rice straw are mixed and then mixed with water. This step is to achieve a uniform state of fully mixed fibers. During the mixing process, some chemicals such as alkaline substances and bleaching agents are added to adjust the properties and color of the fibers.

Thirdly, paper-making and drying. The next step is paper-making. The paper-making master puts the mixed pulp on a frame and uses special tools to evenly spread the pulp to form the initial shape of the paper. This process requires high-level skills and rich experience to ensure that the paper is evenly thick without impurities. Then, the copied paper is dried, which takes a certain amount of time to ensure that the paper is moderately dry.

Fourthly, cutting and sorting. After the paper is dry, it enters the cutting process. According to different needs, the paper is cut into appropriate sizes and shapes. Then it is sorted to remove impurities and poor parts in the paper to achieve a certain quality standard for each sheet of paper.

Finally, quality inspection and packaging of finished products. Quality checks are conducted on each batch of Xuan paper to ensure that it meets the specified standards. Then it is packaged, usually with paper or cloth packaging bags, to protect Xuan paper from damage by external environment.

Thus, a magical journey from raw materials to finished products has ended. Although the production process of Xuan paper is complex, every step is full of craftsmans' dedication and wisdom. It is these carefully crafted Xuan papers that provide endless creative possibilities for Chinese calligraphy and painting art.

Finally, quality inspection and packaging of finished products. Quality checks are conducted on each batch of Xuan paper to ensure that it meets the specified standards. Then it is packaged, usually with paper or cloth packaging bags, to protect Xuan paper from damage by external environment.

Thus, a magical journey from raw materials to finished products has ended. Although the production process of Xuan paper is complex, every step is full of craftsmans' dedication and wisdom. It is these carefully crafted Xuan papers that provide endless creative possibilities for Chinese calligraphy and painting art.

将树皮和稻草的纤维混合后,加入适量的水进行搅拌。这一步的目的是使纤维充分混合,达到均匀的状态。在搅拌的过程中,还需加入一些化学物质,如碱性物质和漂白剂,以调整纤维的性质和颜色。

【宣纸】超多笔画6千划练习楷书描红毛笔软笔字帖宣纸初学入门培训班送视售价:13.80元 领券价:11元 邮费:0.00

【宣纸】赵孟俯行书典范作品梅花诗描红长卷临摹毛笔字帖宣纸3遍装6米长卷售价:19.80元 领券价:19.8元 邮费:0.00

上一篇:宣纸在国际艺术界的地位与影响

下一篇:宣纸的多样性:了解不同种类的宣纸

相关内容

热门资讯

传统与现代:解读宣纸的独特魅力

摘要:

宣纸凭借其独特工艺和魅力,融合传统与现代,展现中华文化深厚底蕴。其细腻质地、吸墨润墨及耐久...

宣纸——传统工艺与现代审美的完...

宣纸是传统工艺与现代审美的完美结合,以青檀树皮为原料,经复杂工艺制成,具有深厚文化底蕴和艺术价值。它...

宣纸在当代艺术创作中的应用

摘要:

宣纸在当代艺术中广泛应用,对传统文化有传承作用,促进艺术创新,并提升作品观赏性和收藏价值。...

宣纸的多样性:从古至今的艺术创...

本文探讨了宣纸的多样性和从古至今的艺术创新。宣纸种类繁多,具有独特性能,被用于各种艺术创作。从古代的...

书法与绘画的绝配——宣纸的独特...

摘要:

宣纸作为中国传统文化艺术材料,以其独特制造工艺和优良物理特性,成为书法与绘画的绝配。其原材...

宣纸的艺术世界:中国千年工艺的...

宣纸作为中国千年工艺的瑰宝,以其独特材质和细腻纹理成为艺术创作的重要载体和文化象征。其千年传承的工艺...

宣纸的独特之处:为何它是艺术家...

摘要:

宣纸因独特原材料和精湛制作工艺,具有吸墨润墨性,是艺术创作的首选。其文化价值传承,使宣纸成...

宣纸技艺传承与发展:探索现代艺...

本文探讨宣纸技艺的传承与发展,指出其作为中国传统文化重要载体的独特性,并分析现代艺术如何借助宣纸技艺...

宣纸与书法艺术:千年传承的完美...

摘要:宣纸与书法艺术相得益彰,共同传承中华文化精髓。宣纸独特质地为书法提供创作基础,书法深邃内涵赋予...

宣纸的独特之处:为何成为艺术家...

宣纸因独特制作工艺、卓越物理特性、丰富文化内涵,成为艺术家首选。其吸墨、润墨性强,可展现丰富层次和立...