宣纸的历史渊源与制作过程揭秘

势大力沉

2025-01-11 18:54:51

0次

**宣纸的历史渊源与制作过程揭秘**

一、历史渊源

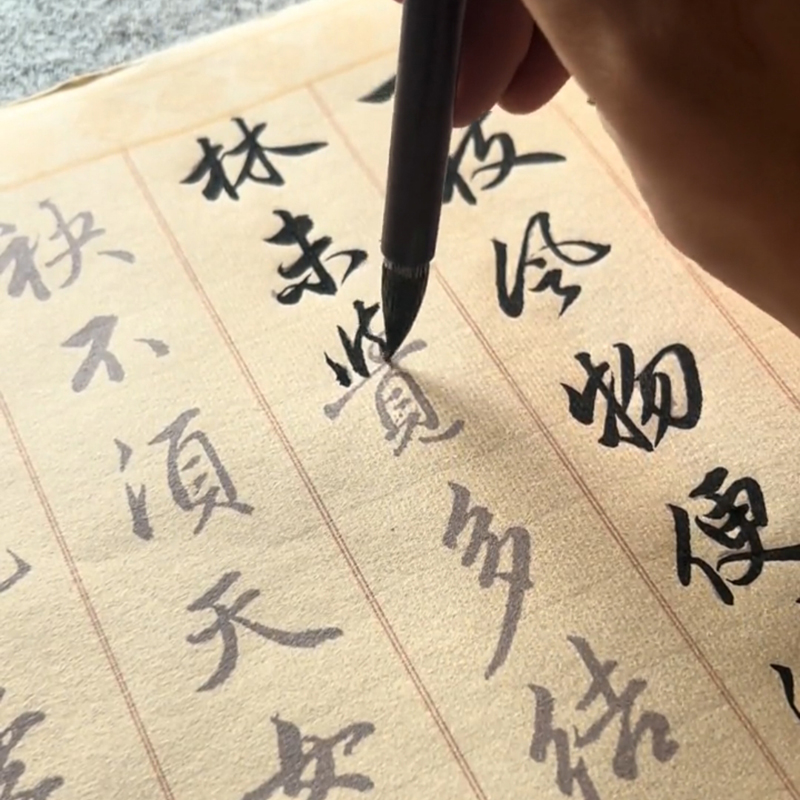

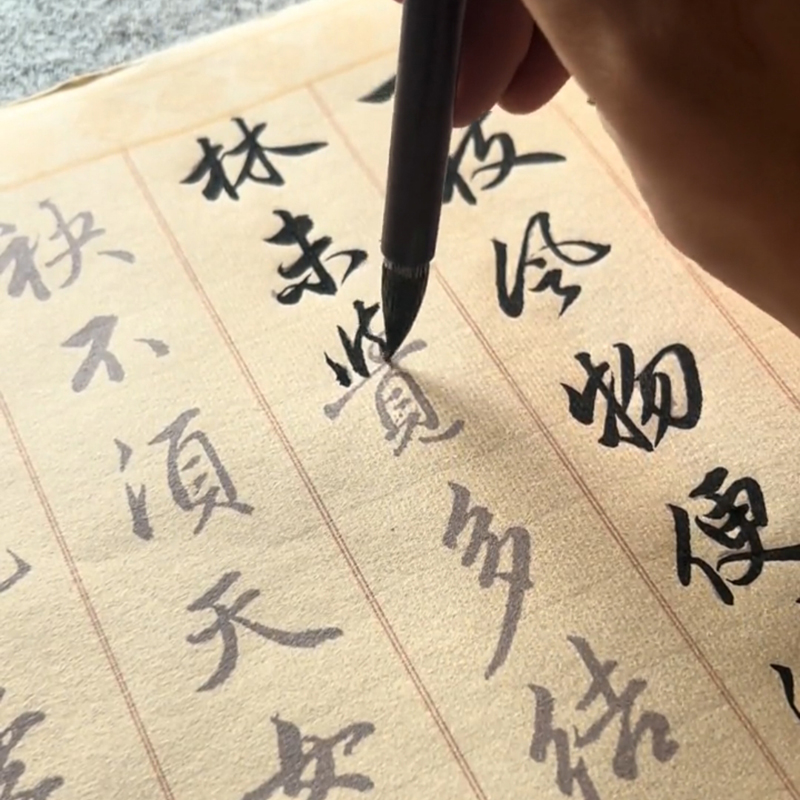

宣纸,作为中国传统的四大名纸之一,拥有着悠久的历史和深厚的文化底蕴。它的起源可以追溯到唐朝,经过宋、元、明、清等朝代的不断发展和完善,逐渐形成了独特的制作工艺和艺术风格。宣纸以其独特的润墨性、防蛀耐久、质韧绵软等特点,成为书法、绘画、印刷等艺术领域的首选材料。

二、制作过程

宣纸的制作过程大致可以分为以下七个步骤:

1. 原材料的准备:选用优质的原材料,主要是青檀树皮和沙石楠的根皮等植物纤维作为主要原料,经过浸泡、晒干等工序,使其成为制作宣纸的基础材料。

2. 晒白:将原材料进行漂白处理,使其颜色变白,这一步通常采用日光晒白的方法。

3. 打浆:将漂白后的原材料进行打浆处理,使其成为均匀的纸浆。

4. 抄纸:将纸浆放置在特制的抄纸网上,通过摇动抄纸网上的水槽,使纸浆均匀地分布在抄纸网上,形成薄薄的纸膜。

5. 晒纸:将抄好的纸膜放在阳光下晾晒,使其干燥。这一步也是利用了天然的阳光资源,使宣纸更加自然、纯净。

6. 剪裁:将晒干后的纸张进行剪裁,使其成为合适的尺寸和形状。

7. 检验与包装:对剪裁好的纸张进行质量检验,将合格的纸张进行包装,然后销往全国各地。

三、英文翻译

Revealing the History and Production Process of Xuan Paper

6. 剪裁:将晒干后的纸张进行剪裁,使其成为合适的尺寸和形状。

7. 检验与包装:对剪裁好的纸张进行质量检验,将合格的纸张进行包装,然后销往全国各地。

三、英文翻译

Revealing the History and Production Process of Xuan Paper

I. History Origin

Xuan paper, one of the four famous traditional Chinese papers, has a long history and profound cultural heritage. Its origin can be traced back to the Tang Dynasty, and through continuous development and improvement in the Song, Yuan, Ming, and Qing dynasties, it gradually formed a unique production process and artistic style. With its unique ink absorption, moth-proof durability, toughness, softness, and other characteristics, Xuan paper has become the preferred material for calligraphy, painting, printing, and other artistic fields.

II. Production Process

The production process of Xuan paper can be roughly divided into seven steps:

1. Raw Material Preparation: Select high-quality raw materials mainly from the bark of the Qingtao tree and the roots of the Shannannan tree as the main raw materials, and then process them through soaking and drying to become the foundation of Xuan paper production.

2. Bleaching: Bleach the raw materials to make them whiter, usually using sunlight bleaching methods.

3. Pulp Making: Pulp the bleached raw materials to make a uniform pulp.

4. Paper Making: Place the pulp on a specially made paper-making net, and evenly distribute the pulp on the net by shaking the water tank on the net to form a thin paper membrane.

5. Drying: Drying the paper membrane in the sun to make it dry. This step also utilizes natural sunlight resources to make Xuan paper more natural and pure.

6. Cutting: Cut the dried paper into appropriate sizes and shapes after drying.

7. Quality Check and Packaging: Conduct quality checks on the cut paper, package the qualified paper, and then sell it throughout China.

I. History Origin

Xuan paper, one of the four famous traditional Chinese papers, has a long history and profound cultural heritage. Its origin can be traced back to the Tang Dynasty, and through continuous development and improvement in the Song, Yuan, Ming, and Qing dynasties, it gradually formed a unique production process and artistic style. With its unique ink absorption, moth-proof durability, toughness, softness, and other characteristics, Xuan paper has become the preferred material for calligraphy, painting, printing, and other artistic fields.

II. Production Process

The production process of Xuan paper can be roughly divided into seven steps:

1. Raw Material Preparation: Select high-quality raw materials mainly from the bark of the Qingtao tree and the roots of the Shannannan tree as the main raw materials, and then process them through soaking and drying to become the foundation of Xuan paper production.

2. Bleaching: Bleach the raw materials to make them whiter, usually using sunlight bleaching methods.

3. Pulp Making: Pulp the bleached raw materials to make a uniform pulp.

4. Paper Making: Place the pulp on a specially made paper-making net, and evenly distribute the pulp on the net by shaking the water tank on the net to form a thin paper membrane.

5. Drying: Drying the paper membrane in the sun to make it dry. This step also utilizes natural sunlight resources to make Xuan paper more natural and pure.

6. Cutting: Cut the dried paper into appropriate sizes and shapes after drying.

7. Quality Check and Packaging: Conduct quality checks on the cut paper, package the qualified paper, and then sell it throughout China.

【宣纸】超多笔画6千划练习楷书描红毛笔软笔字帖宣纸初学入门培训班送视售价:13.80元 领券价:11元 邮费:0.00

【宣纸】赵孟俯行书典范作品梅花诗描红长卷临摹毛笔字帖宣纸3遍装6米长卷售价:19.80元 领券价:19.8元 邮费:0.00

下一篇:书画家的得力助手——宣纸

相关内容

热门资讯

传统与现代:解读宣纸的独特魅力

摘要:

宣纸凭借其独特工艺和魅力,融合传统与现代,展现中华文化深厚底蕴。其细腻质地、吸墨润墨及耐久...

宣纸——传统工艺与现代审美的完...

宣纸是传统工艺与现代审美的完美结合,以青檀树皮为原料,经复杂工艺制成,具有深厚文化底蕴和艺术价值。它...

宣纸在当代艺术创作中的应用

摘要:

宣纸在当代艺术中广泛应用,对传统文化有传承作用,促进艺术创新,并提升作品观赏性和收藏价值。...

宣纸的多样性:从古至今的艺术创...

本文探讨了宣纸的多样性和从古至今的艺术创新。宣纸种类繁多,具有独特性能,被用于各种艺术创作。从古代的...

书法与绘画的绝配——宣纸的独特...

摘要:

宣纸作为中国传统文化艺术材料,以其独特制造工艺和优良物理特性,成为书法与绘画的绝配。其原材...

宣纸的艺术世界:中国千年工艺的...

宣纸作为中国千年工艺的瑰宝,以其独特材质和细腻纹理成为艺术创作的重要载体和文化象征。其千年传承的工艺...

宣纸的独特之处:为何它是艺术家...

摘要:

宣纸因独特原材料和精湛制作工艺,具有吸墨润墨性,是艺术创作的首选。其文化价值传承,使宣纸成...

宣纸技艺传承与发展:探索现代艺...

本文探讨宣纸技艺的传承与发展,指出其作为中国传统文化重要载体的独特性,并分析现代艺术如何借助宣纸技艺...

宣纸与书法艺术:千年传承的完美...

摘要:宣纸与书法艺术相得益彰,共同传承中华文化精髓。宣纸独特质地为书法提供创作基础,书法深邃内涵赋予...

宣纸的独特之处:为何成为艺术家...

宣纸因独特制作工艺、卓越物理特性、丰富文化内涵,成为艺术家首选。其吸墨、润墨性强,可展现丰富层次和立...