探索宣纸的奥秘:从原料到成品

势大力沉

2025-01-18 12:27:45

0次

探索宣纸的奥秘:从原料到成品

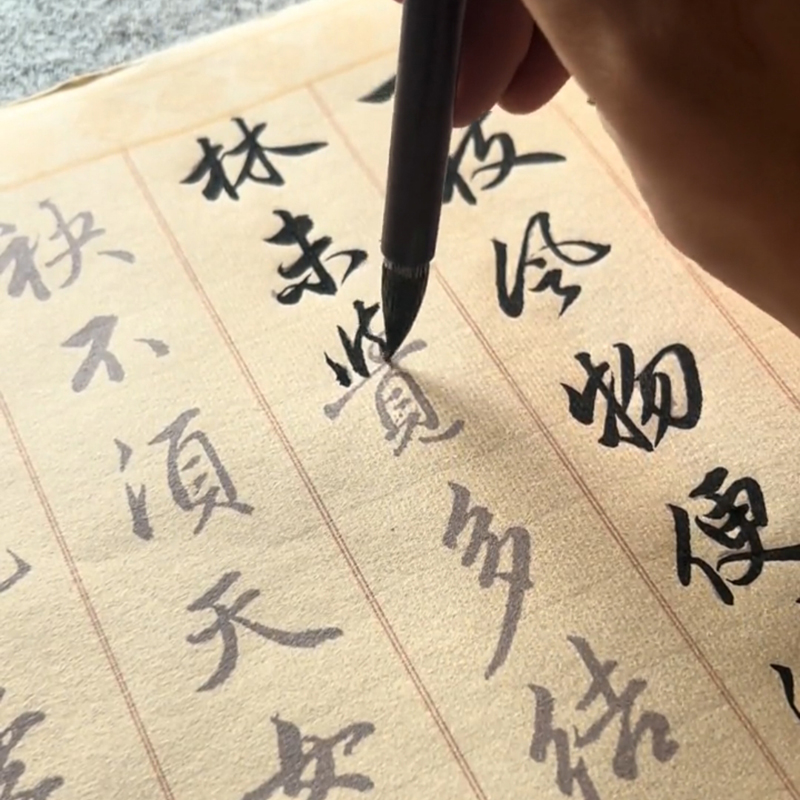

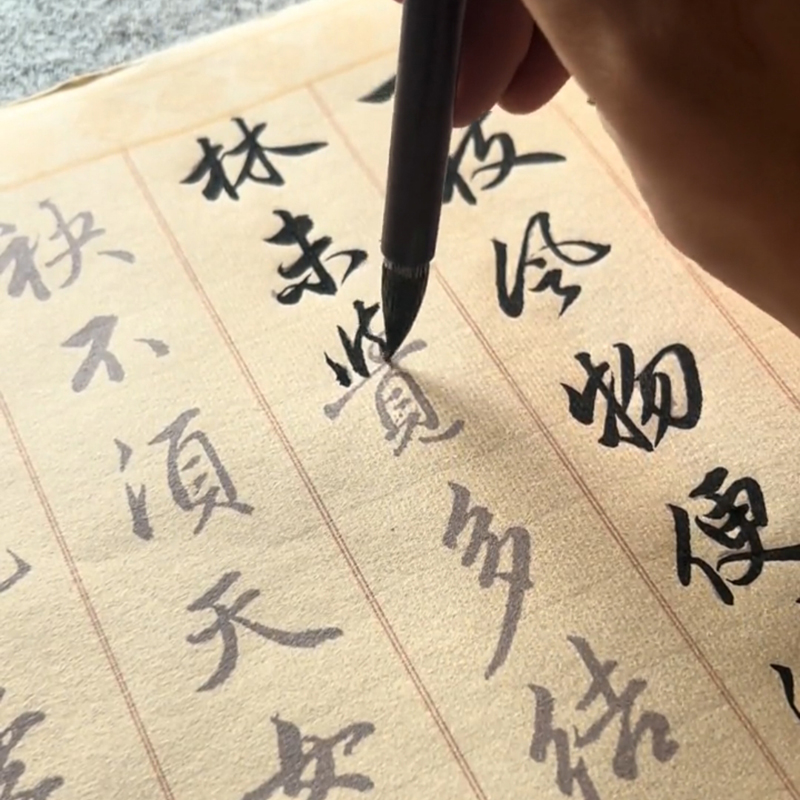

在中国的传统艺术中,宣纸扮演着不可或缺的角色。它以其独特的质地和历史背景,成为了中国书画艺术的代表。那么,让我们一同探索宣纸的奥秘,从其原料到成品的过程。

一、原料的采集与处理

宣纸的主要原料是青檀树皮和沙田稻草。这两种原料首先需要进行采集和处理。青檀树皮需在特定地区、特定时间进行采集,并经过多次洗涤、漂白、脱胶等处理,以达到提取所需成分的目的。而沙田稻草的选取则需要优质的稻田草作为首选。所有原料都必须严格挑选和分类,保证每一份都达到最好的质量。

二、浆料的调配与沉淀

选好的原料被加工成浆料后,经过一定的调配比例进行混合,其中还需要添加一定比例的清水,帮助调和各种原料的特性。接着进行沉淀,使得各原料中的有用成分得到有效的分离和沉淀。这一过程需控制时间、温度等条件,以使各成分能够充分反应并沉淀下来。

三、抄纸与晒纸

在经过浆料调配和沉淀后,接下来就是抄纸和晒纸的步骤。抄纸需要专业技巧,即将调和好的浆料用专门的工具抄写于细密的纸张上,以形成均匀的纸张层。随后在日光下晾晒,直到其达到合适的干燥程度。这个过程需要根据气候和天气状况调整晒纸的技巧和策略,确保纸质的均匀和坚韧。

四、最后的修整与包装

当所有的宣纸制作完毕之后,最后需要进行的就是修整和包装工作。在这一过程中,技术人员对宣纸进行切割、折叠等修整工作,然后将其整理成适当的大小和形状。接着对成品进行检验和包装,保证每一张宣纸都能达到最高质量的标准。

在将这个过程转化成英文后:

The Mystery of Xuan Paper: From Raw Materials to Finished Product

二、浆料的调配与沉淀

选好的原料被加工成浆料后,经过一定的调配比例进行混合,其中还需要添加一定比例的清水,帮助调和各种原料的特性。接着进行沉淀,使得各原料中的有用成分得到有效的分离和沉淀。这一过程需控制时间、温度等条件,以使各成分能够充分反应并沉淀下来。

三、抄纸与晒纸

在经过浆料调配和沉淀后,接下来就是抄纸和晒纸的步骤。抄纸需要专业技巧,即将调和好的浆料用专门的工具抄写于细密的纸张上,以形成均匀的纸张层。随后在日光下晾晒,直到其达到合适的干燥程度。这个过程需要根据气候和天气状况调整晒纸的技巧和策略,确保纸质的均匀和坚韧。

四、最后的修整与包装

当所有的宣纸制作完毕之后,最后需要进行的就是修整和包装工作。在这一过程中,技术人员对宣纸进行切割、折叠等修整工作,然后将其整理成适当的大小和形状。接着对成品进行检验和包装,保证每一张宣纸都能达到最高质量的标准。

在将这个过程转化成英文后:

The Mystery of Xuan Paper: From Raw Materials to Finished Product

Firstly, the collection and processing of raw materials. The main raw materials of Xuan paper are the bark of the Qingyan tree and rice straw from Shatian paddy fields. These materials need to be collected and processed through multiple steps such as washing, bleaching, and degumming to extract the desired components. All raw materials must be strictly selected and classified to ensure the best quality.

Secondly, the preparation and sedimentation of pulp. After the selected raw materials are processed into pulp, they are mixed in a certain proportion with the addition of a certain proportion of water to help balance the characteristics of the various raw materials. Then, sedimentation is carried out to effectively separate and precipitate the useful components in each raw material. This process requires control of factors such as time and temperature to allow for full reaction and precipitation of the components.

Thirdly, paper making and drying. After the preparation and sedimentation of the pulp, the next step is paper making and drying. Paper making requires professional skills, which involves using specialized tools to write the mixed pulp onto a fine-mesh paper to form a uniform layer of paper. Then, it is left to dry in the sun until it reaches an appropriate level of dryness. This process requires adjusting the techniques and strategies for paper drying based on climate and weather conditions to ensure a uniform and tough paper quality.

Finally, finishing and packaging. When all Xuan paper production is complete, the final step is finishing and packaging. In this process, technicians perform cutting, folding, and other finishing work on the Xuan paper to organize it into appropriate sizes and shapes. Then, the finished products are inspected and packaged to ensure that each sheet of Xuan paper meets the highest quality standards.

这就是宣纸从原料到成品的整个制作过程。每一道工序都体现了中国工艺的精湛和独特性,也使得宣纸成为了中国传统文化的瑰宝。

Firstly, the collection and processing of raw materials. The main raw materials of Xuan paper are the bark of the Qingyan tree and rice straw from Shatian paddy fields. These materials need to be collected and processed through multiple steps such as washing, bleaching, and degumming to extract the desired components. All raw materials must be strictly selected and classified to ensure the best quality.

Secondly, the preparation and sedimentation of pulp. After the selected raw materials are processed into pulp, they are mixed in a certain proportion with the addition of a certain proportion of water to help balance the characteristics of the various raw materials. Then, sedimentation is carried out to effectively separate and precipitate the useful components in each raw material. This process requires control of factors such as time and temperature to allow for full reaction and precipitation of the components.

Thirdly, paper making and drying. After the preparation and sedimentation of the pulp, the next step is paper making and drying. Paper making requires professional skills, which involves using specialized tools to write the mixed pulp onto a fine-mesh paper to form a uniform layer of paper. Then, it is left to dry in the sun until it reaches an appropriate level of dryness. This process requires adjusting the techniques and strategies for paper drying based on climate and weather conditions to ensure a uniform and tough paper quality.

Finally, finishing and packaging. When all Xuan paper production is complete, the final step is finishing and packaging. In this process, technicians perform cutting, folding, and other finishing work on the Xuan paper to organize it into appropriate sizes and shapes. Then, the finished products are inspected and packaged to ensure that each sheet of Xuan paper meets the highest quality standards.

这就是宣纸从原料到成品的整个制作过程。每一道工序都体现了中国工艺的精湛和独特性,也使得宣纸成为了中国传统文化的瑰宝。

【宣纸】超多笔画6千划练习楷书描红毛笔软笔字帖宣纸初学入门培训班送视售价:13.80元 领券价:11元 邮费:0.00

In the traditional art of China, Xuan paper plays an indispensable role. With its unique texture and historical background, it has become a representative of Chinese painting and calligraphy art. Now, let's explore the mystery of Xuan paper, from its raw materials to the finished product.

【宣纸】赵孟俯行书典范作品梅花诗描红长卷临摹毛笔字帖宣纸3遍装6米长卷售价:19.80元 领券价:19.8元 邮费:0.00

上一篇:宣纸之美:中国传统工艺的精髓

下一篇:宣纸画作:东方美学的生动展现

相关内容

热门资讯

传统与现代:解读宣纸的独特魅力

摘要:

宣纸凭借其独特工艺和魅力,融合传统与现代,展现中华文化深厚底蕴。其细腻质地、吸墨润墨及耐久...

宣纸——传统工艺与现代审美的完...

宣纸是传统工艺与现代审美的完美结合,以青檀树皮为原料,经复杂工艺制成,具有深厚文化底蕴和艺术价值。它...

宣纸在当代艺术创作中的应用

摘要:

宣纸在当代艺术中广泛应用,对传统文化有传承作用,促进艺术创新,并提升作品观赏性和收藏价值。...

宣纸的多样性:从古至今的艺术创...

本文探讨了宣纸的多样性和从古至今的艺术创新。宣纸种类繁多,具有独特性能,被用于各种艺术创作。从古代的...

书法与绘画的绝配——宣纸的独特...

摘要:

宣纸作为中国传统文化艺术材料,以其独特制造工艺和优良物理特性,成为书法与绘画的绝配。其原材...

宣纸的艺术世界:中国千年工艺的...

宣纸作为中国千年工艺的瑰宝,以其独特材质和细腻纹理成为艺术创作的重要载体和文化象征。其千年传承的工艺...

宣纸的独特之处:为何它是艺术家...

摘要:

宣纸因独特原材料和精湛制作工艺,具有吸墨润墨性,是艺术创作的首选。其文化价值传承,使宣纸成...

宣纸技艺传承与发展:探索现代艺...

本文探讨宣纸技艺的传承与发展,指出其作为中国传统文化重要载体的独特性,并分析现代艺术如何借助宣纸技艺...

宣纸与书法艺术:千年传承的完美...

摘要:宣纸与书法艺术相得益彰,共同传承中华文化精髓。宣纸独特质地为书法提供创作基础,书法深邃内涵赋予...

宣纸的独特之处:为何成为艺术家...

宣纸因独特制作工艺、卓越物理特性、丰富文化内涵,成为艺术家首选。其吸墨、润墨性强,可展现丰富层次和立...